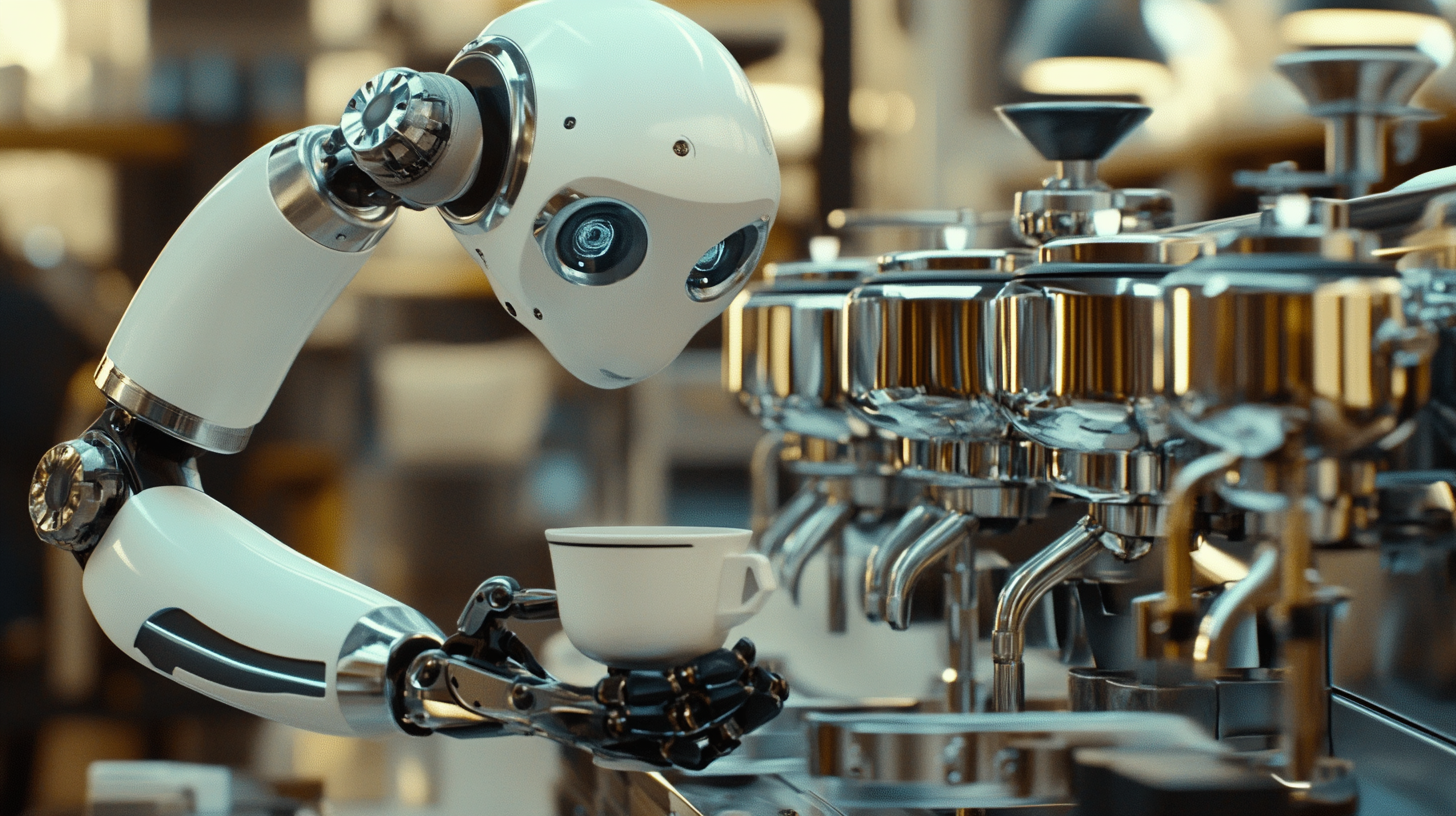

In recent years, the coffee industry has witnessed a remarkable evolution with the rise of automated solutions, among which the Robotic Barista Coffee Machine stands out as a game-changer. Designed to enhance efficiency and consistency in coffee preparation, these machines promise to redefine customer experiences. However, global buyers eager to integrate this innovative technology into their operations often encounter a myriad of challenges that can complicate the sourcing process. From navigating complex supply chains to ensuring compatibility with existing systems, the journey to acquiring a Robotic Barista Coffee Machine is fraught with potential obstacles.

Moreover, the challenges are not merely logistical; they encompass a deeper understanding of market trends, technological advancements, and consumer expectations. As buyers assess the potential return on investment and feasibility of implementing such advanced machinery, they must also consider variations in quality and service offered by different manufacturers. This blog will delve into the specific hurdles faced by global buyers and provide insights into strategies for successful sourcing of Robotic Barista Coffee Machines, facilitating an informed approach to embracing this cutting-edge coffee technology.

The sourcing of robotic barista coffee machines presents significant challenges for global buyers, particularly within the complexity of international supply chains. As buyers navigate through various hurdles, the influence of geopolitical factors and trade policies becomes increasingly apparent. Current trends reflect a growing unpredictability due to rising unilateralism and protectionism, which add layers of difficulty in establishing reliable supply chains. This is especially true for complex machinery like robotic coffee machines that rely on components sourced from multiple countries. Recent developments indicate that while some regions face trade restrictions, others, such as China, continue to demonstrate resilience in their economic activities. China's sustained economic growth serves as a stabilizing force in the global market, offering opportunities for buyers looking to source advanced technologies. However, navigating the Chinese market requires an understanding of its intricate supply chain dynamics, including local sourcing options and regulatory considerations. In light of these factors, global buyers must not only contend with the immediate challenges of procurement but also adopt strategic approaches to optimize their sourcing operations. This may involve diversifying suppliers, investing in local partnerships, or leveraging technology to enhance supply chain visibility. As the landscape of global trade continues to evolve, staying informed about these complexities will be crucial for buyers in the robotic coffee machine sector.

Evaluating quality standards across different manufacturers and countries is a critical challenge for global buyers sourcing robotic barista coffee machines. The robotic coffee machine market is diverse, with various companies offering products that may look similar but differ significantly in functionality, reliability, and quality. Buyers often encounter inconsistencies in standards and certifications between regions, making it imperative to do thorough research and due diligence prior to purchasing.

One of the primary issues buyers face is the lack of universally accepted quality benchmarks. Different countries have distinct regulations and manufacturing practices, which means a machine that meets high standards in one country may not be comparable to another's. For instance, European manufacturers might comply with stringent safety and performance certifications, while others may prioritize cost-effectiveness, leading to variations in overall build quality and service longevity. This discrepancy can make it difficult for buyers to ascertain which machines will maintain quality over time and deliver optimal performance in a commercial setting.

Additionally, communication barriers and cultural differences can affect quality assurance processes. Buyers may find it challenging to convey their requirements to manufacturers in different countries, leading to a misalignment of expectations. Establishing quality control measures during the production process becomes crucial. Therefore, global buyers must invest time in building relationships with suppliers, understanding their quality assurance protocols, and possibly conducting on-site inspections to ensure alignment in quality standards before finalizing their purchases.

Navigating the landscape of robotic barista coffee machines poses significant challenges for global buyers, particularly when it comes to regulatory compliance and certifications. As the industry expands, different countries implement various safety standards and operational regulations that must be adhered to. This divergence can create confusion for manufacturers and buyers alike, as a machine that is compliant in one country may not meet the required criteria in another. Understanding each market's specific requirements is essential for ensuring that investments in robotic technology yield a successful return.

Furthermore, the certification process for robotic baristas often involves rigorous testing and documentation, which can be time-consuming and costly. Buyers must conduct thorough research into applicable certifications, such as UL, CE, or NSF, depending on the geographical location. In some regions, local authorities may require additional assessments or approvals, adding another layer of complexity to the procurement process. Buyers must not only evaluate the machine's functionality and efficiency but also ensure that it aligns with all necessary legal frameworks to avoid potential fines or market entry barriers.

The rapidly evolving nature of technology also complicates compliance efforts. As innovations are introduced, regulatory bodies frequently update their standards to address new safety or operational challenges. Buyers must stay informed about these changes and adapt their sourcing strategies accordingly. Collaborating with suppliers who have experience navigating these regulatory landscapes can help streamline the compliance process, allowing global buyers to make informed decisions and mitigate risks associated with their investments in robotic barista solutions.

Sourcing robotic barista coffee machines has become increasingly complex for global buyers, particularly when it comes to navigating language barriers and cultural differences in business negotiations. A report by MarketsandMarkets projects the coffee machine market, including robotic options, to reach USD 4.2 billion by 2026, indicating a growing demand. However, this expansion presents unique challenges, especially for companies engaging with suppliers from diverse linguistic and cultural backgrounds.

Language barriers can significantly impede clear communication, leading to misunderstandings that may affect contract terms, product specifications, and timelines. According to a survey by the Common Sense Advisory, 72% of consumers are more likely to buy a product if information is available in their native language. This statistic underscores the importance of effective translation and localization strategies when negotiating with international suppliers. Buyers may need to invest in professional translation services to ensure that technical details are accurately conveyed and agreed upon.

Cultural differences also play a crucial role in negotiations. According to Hofstede's cultural dimensions theory, dimensions such as individualism versus collectivism and uncertainty avoidance can influence negotiation styles. For instance, buyers from collectivist cultures may prioritize relationship-building, while those from individualist cultures might focus on direct negotiations. Understanding these cultural nuances is essential for building trust and achieving successful outcomes. Equipping global buyers with knowledge of their counterparts' cultural contexts can transform potential conflicts into collaborative opportunities in the sourcing process.

When sourcing robotic barista coffee machines globally, one of the most significant hurdles faced by buyers is the complexity of logistics and shipping. The intricacies involved in international trade necessitate a firm understanding of the various factors affecting the movement of goods across borders. From compliance with customs regulations to arranging transportation, buyers must navigate a labyrinth of challenges that can delay delivery and increase costs if not managed proficiently.

International shipping often entails dealing with multiple stakeholders, including freight forwarders, customs brokers, and local distributors. Coordinating these parties to ensure seamless logistics can be daunting. Buyers must also factor in the unpredictability of shipping routes influenced by geopolitical events, weather conditions, or sudden shipping policy changes. Such uncertainties can lead to increased shipping times, which is particularly critical in a market where consumer demand for specialty coffee continues to rise.

Additionally, the need for specialized handling of robotic barista machines adds another layer of complexity. These high-tech devices require careful packaging and transportation to prevent damage during transit. Buyers must ensure that their logistics partners are equipped to handle such delicate cargo, which may also involve additional costs. Creating a robust logistics strategy that accounts for these various challenges is essential for global buyers to ensure timely delivery and maintain competitive pricing in the ever-evolving landscape of coffee services.